CONTACTING - COLD TEST

![]()

Your advantages at a glance:

- Best functionality

- Robustness through surface refinement

- Wear-reduced contacting due to spring contacts

- Secure holding and locking of the test specimen in the match plate

- A high number of mating cycles

- Customer-specific design

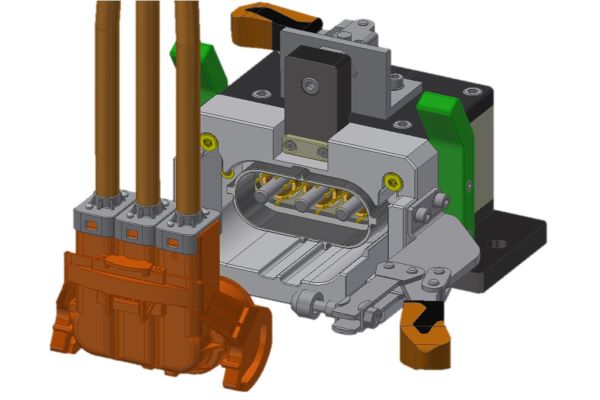

The development and production of complex contacting systems for cold test benches for the automotive industry is one of our core competences. And thanks to our many years of experience and close cooperation with well-known customers, we develop the right solution for every application.

The engine plugs are set-up and locked manually in the exact position on the in-house developed match plate of the workpiece carrier. That allows us to automatically deliver the in-house developed contacting unit in the test bench, which is wired to the measuring equipment, to the match plate.

In order not to damage the engine plug contacts by direct plugging, we use contact modules in the contacting unit which align themselves exactly on the match plate, touch the contact lamella of the engine plug contact with spring contacts and thus ensure a reliable signal transmission to the measuring equipment.

The use of spring contacts, on the one hand, protects engine connectors and, on the other hand, allows high mating cycles.

We would be pleased to develop a custom-made concept for your specific application and look forward to hearing from you.

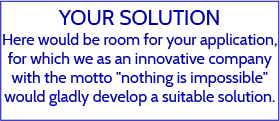

CONTACTING - HOT TEST

![]()

Your advantages at a glance:

- Best functionality

- ECU contacting by spring-loaded contacts

- One holder for several ECU-types

- Secure fixation of the ECU in the holder by a locking mechanism

- Spring-loaded single connector holders

- Wear-reduced contacting

- A high number of mating cycles

- Customer-specific design

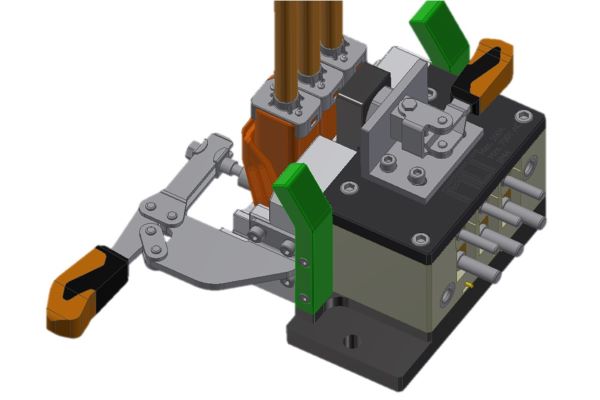

The development and production of complex contacting systems for hot test benches for the automotive industry is one of our core competences. And thanks to our many years of experience and close cooperation with well-known customers, we develop the right solution for every application.

These contacting systems are characterized by the fact that the connector holder is designed for several types of control units. The ECU is inserted into the connector holder, and a unique locking mechanism moves it linearly to the contact modules with spring-loaded contacts, where it is contacted and clamped.

Depending on the customer's requirements, the engine connectors are either plugged-in directly or, in turn, picked up and fixed using contour-exact individual connector holders with spring-loaded contacts and integrated locking.

The use of spring contacts, on the one hand, protects engine connectors and, on the other hand, allows high mating cycles.

We would be pleased to develop a tailor-made concept for your specific application and look forward to hearing from you.

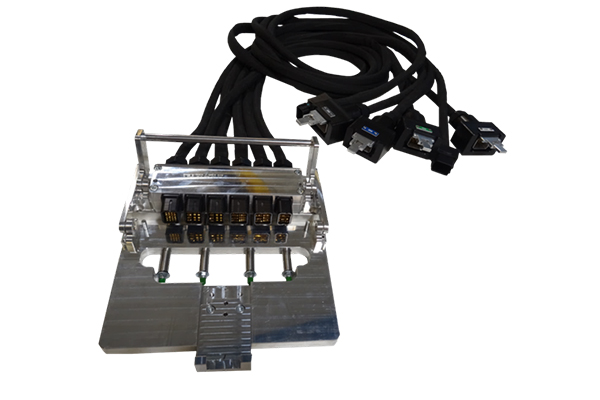

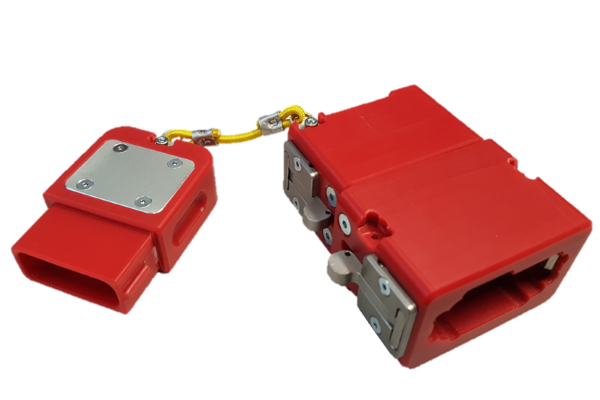

CONTACTING: E - Mobility

Automatic Contacting Systems

![]()

Your advantages at a glance:

- Robustness due to surface refinement

- Position compensation +/-2mm or +/-2° inclination, as well as a radial "finding mechanism".

- Wear-reduced contacting & high number of mating cycles

- Secure signal transmission up to 600A/1000V implemented

- Short-circuit-proof up to 3,5kVpk

- Quick-change system of the contacts, compact design

- For ESD application if required

- With Sense-contacts if required

- Protected against splash water or dust if required (IP44)

- Customer-specific design

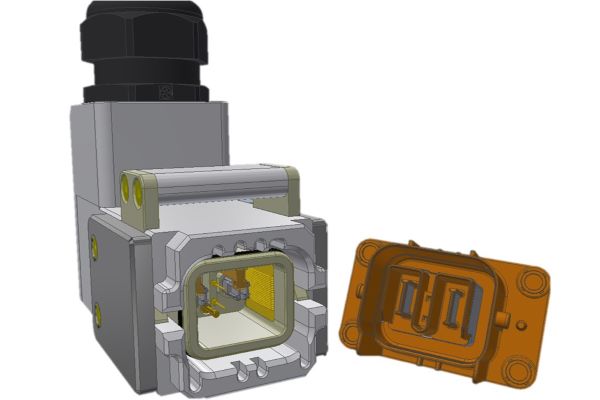

As an environmentally conscious and progressive company, we have recognized the signs of the times, and we have invested a lot of research and development work in contacting systems for electric mobility, both for low-voltage (LV) and high-voltage (HV) applications.

In addition to flawless functionality, robustness through surface refinement, and attractive design, safety is paramount.

Due to the integrated position compensation of the contact module of up to +/-2mm in the plane or +/-2° inclination, as well as, if required, radial "finding mechanism" (360° rotation) for any position of the test specimen coding, the contact module can be accurately fed to the test specimen which may have tolerances in its clamping. By using spring-loaded test contacts or collets in HV applications, the contact module can be brought to the test contacts without wear. In LV applications, the spring-loaded test contacts are pressed against the test specimen contacts, and in HV applications, the collets are pushed without force over the testing contacts and are only radially tensioned in the end position.

Furthermore, the contacting units are characterized by a high number of mating cycles, process-safe use at high currents up to 600A / 1000V, and by the quick-change system of the test contacts/collets.

We would be pleased to develop a tailor-made concept for your specific application and look forward to hearing from you.

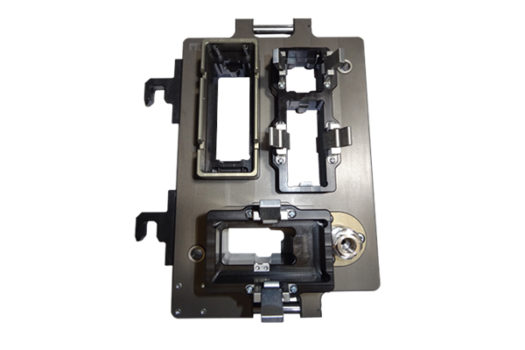

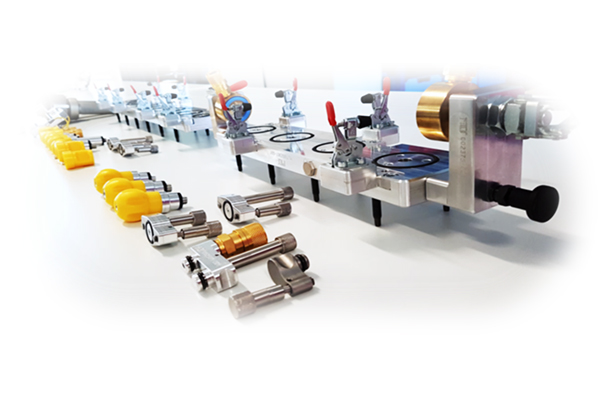

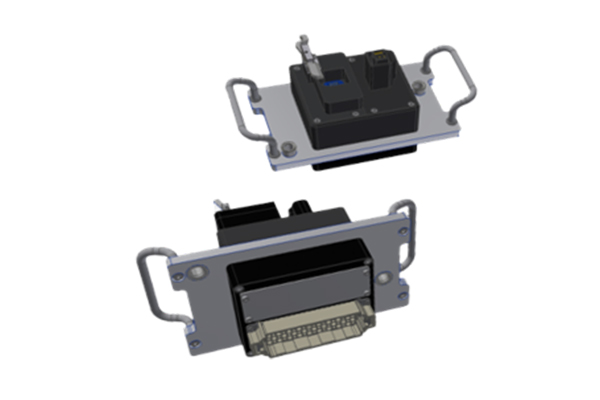

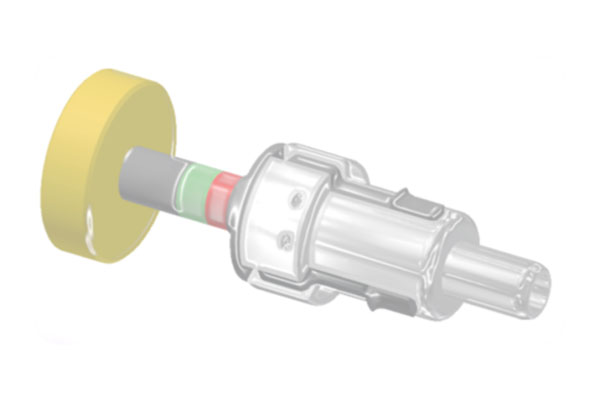

ADAPTER - ELECTRIC

Short or long design

![]()

Your advantages at a glance:

- Best functionality

- Robustness through surface refinement

- Wear-reduced contacting

- Compact design

- A high number of mating cycles

- 1:1 Through wiring or gender change

- spring-loaded single connector holders or direct contacting with original connector

- Military connector holders possible

- safe adaptation via central plug in the test bench

- Connection of m/f, f/f, m/m Plug

- Plug-in and locking system adapted to the respective requirements

- HV version up to 150A - or according to customer requirements

- Customer-specific design

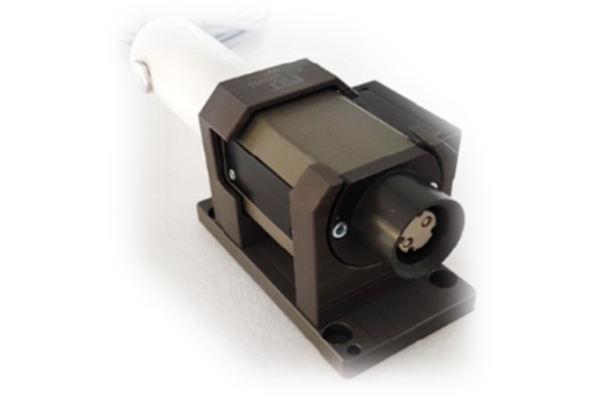

The development and production of complex adapters for cold and hot test benches for the automotive industry is one of our core competences. Thanks to our many years of experience and close cooperation with well-known customers, we develop the right solution for every application.

The main focus is on perfect functionality, robustness through surface finishing, ergonomics (lightweight construction), easy handling, and attractive design.

By means of precisely contoured individual plug holders, the test specimen is picked up without twisting and is guided accurately to the spring-loaded test contacts.

The spring-loaded test contacts are pressed against the test specimen contacts, and no pre-damage to the test specimen occurs by direct plugging.

Furthermore, the adapters are characterized by high mating cycles, process-safe use at high currents (also available as HV version), and sophisticated locking mechanisms for safe locking of the test specimen in the single connector holder.

We would be pleased to develop a tailor-made concept for your specific application and look forward to hearing from you.

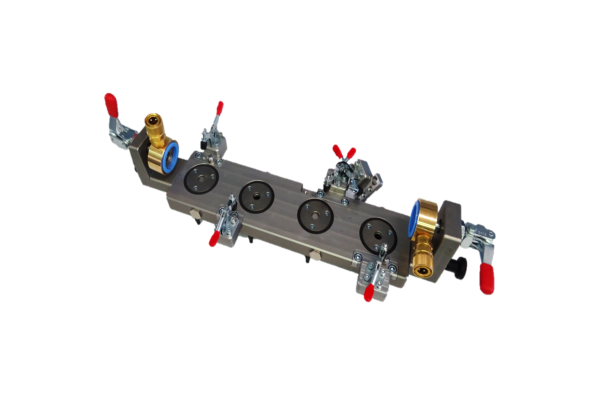

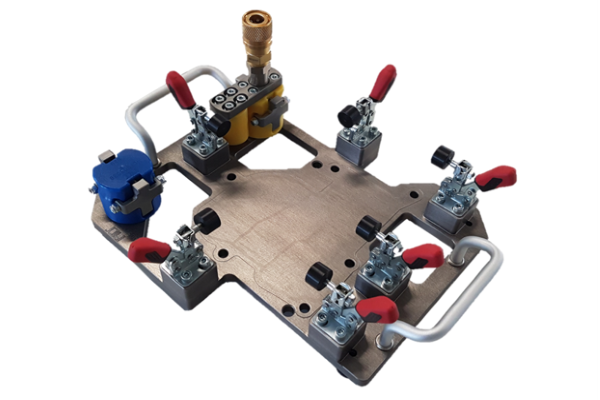

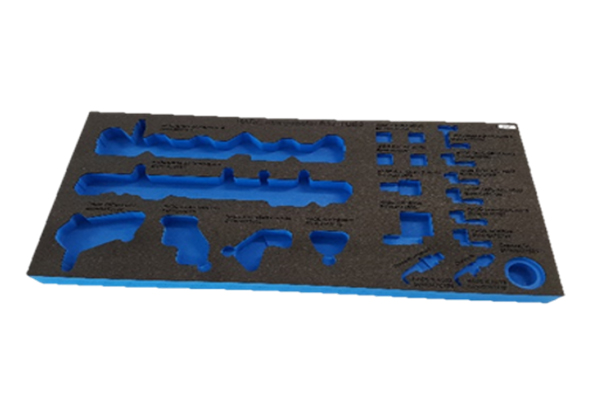

ADAPTER – MEDIA

Manual sealing elements „HADE“.

![]()

Your advantages at a glance:

- Best functionality

- Robustness through surface refinement

- Ergonomic, easy handling

- Lightweight construction

- Secure locking on the test specimen

- even at high pressures up to 10bar

- Process reliability with various media

- Customer-specific design

We have specialized and established ourselves in the field of leak testing of various engine and transmission parts and have developed a wide range of products with exceptional know-how, tailored to the technical requirements and the needs and wishes of our renowned customers.

In addition to complete functionality and robustness through surface refinement, ergonomics (lightweight construction), easy handling, and attractive design are in the foreground.

Furthermore, our manual sealing elements (HADE) convince by safe locking to the test specimen by sophisticated locking mechanisms (expansion, push-pull, ball locking, screw locking, etc.), by excellent tightness even at high pressures up to 10bar, and by process-safe use with different test media (helium, compressed air, oil, fuel, etc.).

We would be pleased to develop a tailor-made concept for your specific application and look forward to hearing from you.

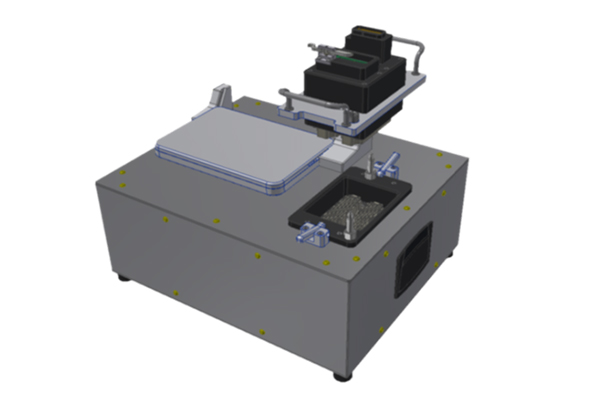

TESTING AND MEASUREMENT TECHNOLOGY

![]()

Your advantages at a glance:

- Best functionality

- Fast, easy and safe adapter control

- Simple operation

- Testing devices can be extended as required using a separate test attachment per adapter

- Broad coverage Adapter types due to 216-pin interface

- Customer-specific design

For each of our adapters, we also offer a suitable adapter test device for electrical continuity and short-circuit testing, either as a practical, mobile table-top device or as a fixed test table, in order to be able to offer our demanding customers the best service in this area as well.

There is an individual slot with spring-loaded contacts for signal transmission for each adapter type.

Alternatively, we also offer test equipment with a central slot with e.g., 216 pins (large cover for adapter types) and matching individual test attachments for each adapter type. Thus, these types of test devices can be expanded as desired with minor software adjustments but without mechanical intervention.

The evaluation is done by an internal test device and the display by laptop, tablet, or similar.

Often a visual inspection of the test contacts is sufficient, which is why we have developed special "test goggles" with drilled pin layout, which are pushed onto the test object to check whether the contacts are mechanically ok, i.e., whether the contact length corresponds to the nominal length or whether contacts are bent.

Upon customer request, test equipment or control tools can also be supplied in practical hard-shell cases or hard foam ETUIs.

We would be pleased to develop a tailor-made concept for your specific application and look forward to hearing from you.

MECHANICS

![]()

Your advantages at a glance:

- Best functionality

- Robustness through surface refinement

- Secure locking

- Highest precision

- Lightweight construction

- Ergonomic, easy handling

- Customer-specific design

Our modern CNC machinery and high in-house production depth enable us to manufacture complex and high-precision parts according to our demanding customers' wishes and requirements.

This results in innovative solutions such as subtracting tools for locking couplings on engine parts, centering mandrels for the precise alignment and fixing of flywheels on crankshafts with an accuracy of 1/100mm or clamping and sealing devices for leak testing of critical components, which have proven themselves in the field over many years.

Our "mechanical parts" impress by ergonomic and straightforward handling, safe locking of the test item, and lightweight construction.

We would be pleased to develop a tailor-made concept for your specific application and look forward to hearing from you.

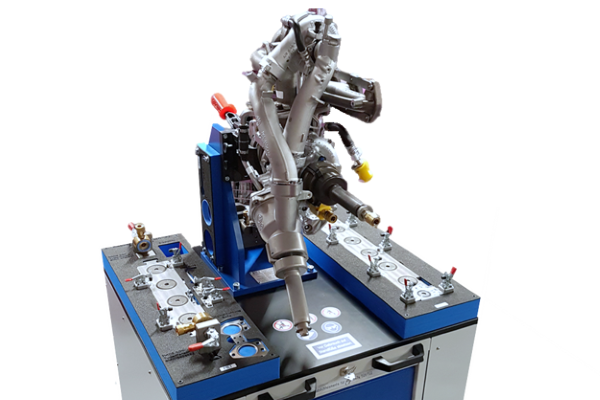

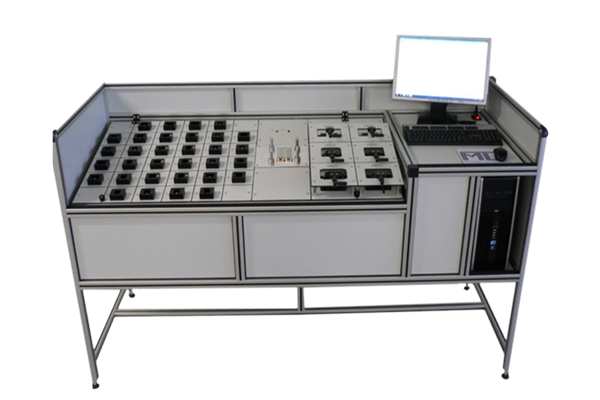

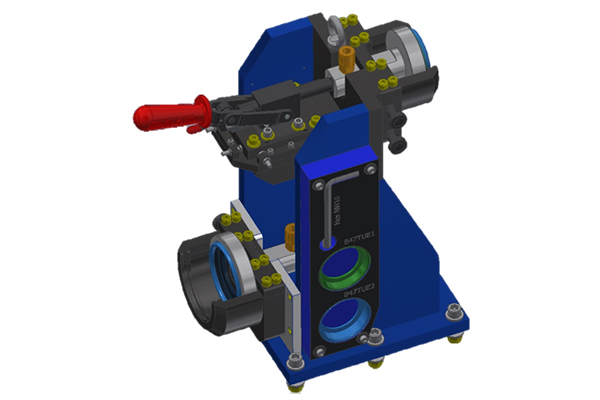

TEST BENCH EQUIPMENT

![]()

Your advantages at a glance:

- Best quality

- Complete conceptual design

- Complete control cabinet assembly

- Clean cable routing and wiring

- Both LV and HV applications

- Compact design

- Customer-specific design

The development, production, and wiring of sophisticated test bench equipment for the fun & off-road vehicle sector are among our core competencies. And thanks to our many years of experience and close cooperation with well-known customers, we develop the right solution for every application. The complete conceptual design, from the construction of the switch cabinets to the laying of cables and wiring, is carried out 100% in-house by our highly qualified specialists.

The test bench equipment impresses for low-voltage as well as for high-voltage applications with the best quality and compact design.

We would be pleased to develop a tailor-made concept for your specific application and look forward to hearing from you.

PROCESS OPTIMIZATION

![]()

Your advantages at a glance:

- Best functionality

- Complete conceptual design including

- Switch cabinet construction,

- Clean cable or hose installation and wiring,

- Programming

- For electrical and pneumatic applications

- Compact design

- Customer-specific design

As a progressive company, we have also established ourselves in the field of process optimization with our compact controller units and inspire our demanding customers. For example, it can be used to automatically check with significant time savings, whether a non-return valve has been installed in the correct position in the assembly line to avoid later damage.

The complete development and conceptual design, from the construction and wiring of the control cabinets to the programming, is carried out 100% in our company, and you receive a complete solution ready for installation.

We develop our compact controller units for both electrical and pneumatic applications in the highest quality and compact design.

We would be pleased to develop a tailor-made concept for your specific application and look forward to hearing from you.

YOUR SOLUTION

![]()

Here would be room for your application,

for which we as an innovative company

with the motto "nothing is impossible"

would gladly develop a suitable solution.